Highly resistant to oxidation and corrosion, this alloy is durable and easy to fabricate. It is composed of 18% chromium and 8% nickel, with low levels of carbon. The most commonly used austenitic stainless steel (though not at Certified Grinding) is type 304 Stainless Steel. Type 303 Stainless Steel is a less expensive, more machinable alternative to similarly composed 304 stainless steel. The additions of 0.15% sulfur or selenium and phosphorus make type 303 the most machinable alloy of the class but slightly reduce its corrosion resistance.ĭespite this, it is still an optimal material for components that require significant machining, such as nuts and bolts, screws, bushings, fasteners, bearings, and components that require significant machining or grinding and require precise tolerances. 303 Stainless Steel is a free-machining grade of 304 Stainless Steel that contains added sulfur or selenium. The base composition of type 303 Stainless Steel is approximately 17% chromium and 8% nickel. The most common austenitic stainless steels are types 303, 304, and 316.Īlthough related, these alloys differ in areas like chemical composition, material capabilities, and cost. At Certified Grinding & Machine, 303 Stainless Steel is our most popular grade our second most popular grade is 416, martensitic stainless steel.Ĭlass 300 Stainless Steel is an austenitic chromium-nickel alloy that is highly corrosion-resistant and non-magnetic, displaying excellent formability and temperature resistance.

#18 8 STAINLESS STEEL VS 316 SERIES#

The most widely used stainless steel is austenitic, with the 300 series being the most popular grade. Their differences are based on their distinct microscopic crystalline structures, each of which lends the steel a specific metallurgical profile. Main Grades of Stainless SteelĪustenitic, ferritic, martensitic, duplex, and precipitation-hardening are the main types of stainless steel alloys. It is essential to consider your final application for the material in order to select the correct type and grade of stainless steel. Since 316 contains 2-3% molybdenum, and molybdenum can improve the pitting resistance, therefore 316 is more resistant to corrosion than 304.Stainless steel comes in a variety of grades and compositions. The price of molybdenum (Mo) is about twice that of nickel (Ni), six times that of chromium (Cr), 316 nickel content is higher than 304, and 316 contains molybdenum, while 304 does not contain it, so the cost of 316 is higher than 304. The price of stainless steel depends on the price of the alloying element and the amount of the alloy (eg Ni, Cr and Mo).

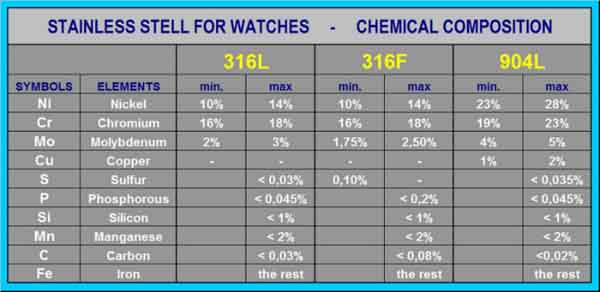

(12.7 mm)ĪISI 304 vs 316 stainless steel cost: Taking steel plates as an example, the cost of 316 is about 1.5 times the cost of 304. Stainless 304 vs 316 mechanical properties SS304 vs SS316 Mechanical PropertiesĪnnealed, Cold finished, ≤ 0.5 in. The following table shows the chemical composition difference between 304 and 316 stainless steel (SS304 vs SS316). SS304 vs SS316 Difference in Chemical Composition AISI 304 has a 18% Cr and 8% Ni and therefore known as 18/8 stainless steel, while AISI 316 stainless steel has a 16% Chromium and 10% Nickel. The addition of molybdenum provides pitting resistance in phosphoric acid, acetic acid and dilute chloride solutions and provides corrosion resistance in sulfurous acid. The main difference between 304 vs 316 stainless steel is that 304 does not contain molybdenum, while 316 contains 2-3% molybdenum and less chromium and more nickel. Difference Between 304 vs 316 Stainless Steel (SS304 vs SS316)

0 kommentar(er)

0 kommentar(er)